-

Address Info

Vadavalli Village, Panapatti Road, Coimbatore - 641 669, Tamil Nadu, INDIA.

-

email us

[email protected]

We have an excellent reputation for producing copper granules as pure as 99.9% copper. Every order that leaves the facility

Aluminum pucks are considered to be one of the basic raw materials in foundries. Aluminum Pucks are circular cylindrical

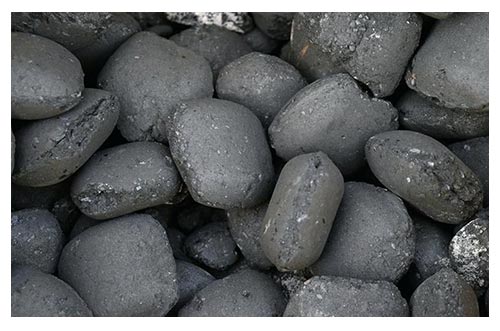

Our new diversified business line manufactures Coal briquette. Coal briquettes is a compressed block of coa

We invest in the most advanced plant and equipment, this is the reason why we are able to process scrap more effectively and produce the highest quality end products. Furthermore, this enables us to operate at maximum efficiency and minimize emissions. We strive to become a zero waste company in the near future.

Our advanced cable granulation technology results in the recovery of copper, lead, steel and plastic from virtually any type of copper cable. Once sampled and graded, the cable is shredded or stripped. Cable stripping is used to remove lead from lead covered copper cable. Shredding is used to reduce the size and remove steel from steel armoured cable. Again the cores of cable are granulated. The granulation process removes the steel and plastic. The plastic residue is processed further to extract any copper left over from granulation.

Shredding material down to optimum size means we produce a high quality product and allows the re-capture of materials for further processing which would otherwise be lost. We have extensive and high-tech shredders for ferrous, non-ferrous and waste electrical equipment. This equipment includes one of the world’s largest breakthrough technology mega-shredders.

Once the metals are recovered through shredding, at InterAsia we employ our own technology for separation of these materials using a number of methods:

These processes produce streams of additional recovered metals, aggregates, rich plastics and a combustible fraction to be converted into energy.